Novel methods for Droplet Generation

We have developed methods to jet droplets with diameters smaller than the nozzle from which they emerge. Some of our methods use a novel driving waveform and a nozzle geometry that permits the jetting of liquid with high particle contents.

This method was firstly presented in the Review of Scientific Instruments 83 115105 (2012).

Principles

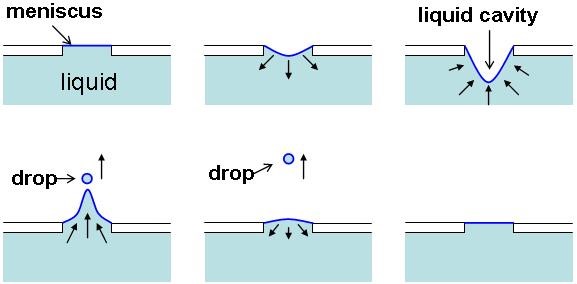

The novel jetting mechanism is based on the production and collapse of a liquid surface (cavity) to produce a high speed drop in response to a pressure driving waveform. This process is illustrated in the upper figure. The process starts when a flat liquid meniscus is formed and retained by the action of a constant pressure. Then, the action of the negative edge of a negative pressure pulse pulls the meniscus back into the liquid reservoir while the meniscus contact line remains pinned to the nozzle edge. The arrival of the positive edge of a pressure pulse produces the collapse of the meniscus cavity which transfers energy to the fluid around the nozzle. The result is a jet that breaks up and forms a quick droplet. Following the action of the constant pressure, the meniscus settles back to its equilibrium position at the nozzle.

Advantages

- Small droplets can be formed from within a much larger nozzle (~3-80 times).

- The likelihood of nozzle blocking is reduced which opens up possibilities to print inks which would otherwise be difficult or impossible to print from a conventional drop-on-demand system.

- A wide range of viscosities is possible (around 1 to ~100 mPa s without heating).

- It can be operated in any orientation (up and down positions have already been tested).

- Our experimental work has found that the proposed mechanism extends the existing limits of the commonly accepted inkjet operating regime.

- Two different sized droplets can be produced from the same nozzle (On Demand).

The technology in action

The video shows a 120 µm droplet of a 2 cP liquid being jetted from a 2 mm nozzle. The droplets contain a 10% volume fraction of 10 µm silver plated glass particles which are hard or impossible to jet by conventional technologies. Images taken with high-speed imaging. We have designed and successfully tested different print-head prototypes based on this invention. These range from large scale systems containing 2 mm sized nozzles down to systems with 60 µm nozzles. In fact, we have also adapted existing commercial print-heads so they can operate under this novel method.

Once the print-heads are made to run under this method, they can still operate under conventional drop on demand and continuous inkjet modes making it ideal for grey-scale or two-sized droplet applications.

This invention was reported in the Review of Scientific Instruments 83, 115105 (2012).

Collaborators: